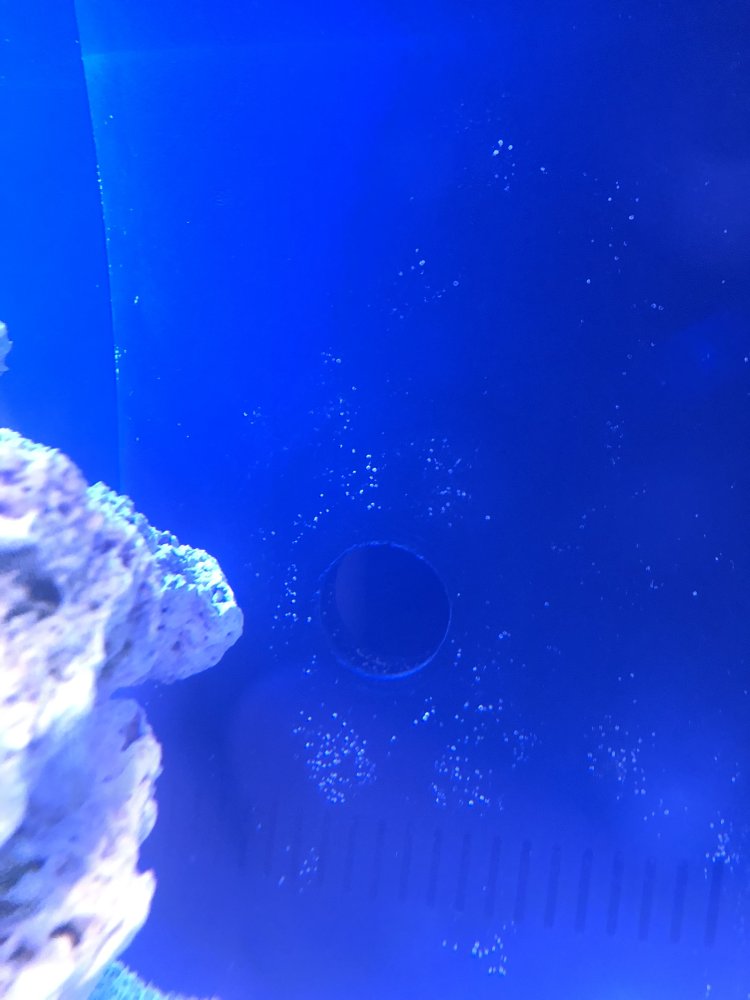

I just purchased a 150 gallon with Dual internal overflows. Each box has 2 holes in the bottom of the tank and the normal slotted intakes in the overflows...BUT the box on the right-hand side has an additional hole in it about 8" up with a bulkhead. I am not sure what the use is for this but it seems to be interfering with me utilizing the overflow properly as water will come into the overflow before it gets to the top of the box.

Any idea what that hole is for and how I would go about plugging it up...I tried to just put a plug in the front of the bulkhead but I can't get it to stop leaking..

Any help is appreciated

Any idea what that hole is for and how I would go about plugging it up...I tried to just put a plug in the front of the bulkhead but I can't get it to stop leaking..

Any help is appreciated