Just modded my asm g3 this past week and I wanted to share my results for anyone else who might be thinking about doing it.

first i thought it was acrylic, but called the company and found out it was in fact extruded PVC. it is very easy to drill.

i used a 1-3/4 hole saw to fit a 1" uniseal. i ended up not using the Uniseal brand, but another i got from McMaster Carr. Same idea, a bit more heavy duty though and a tougher rubber (which actually made it harder to get it to fit). it had the same size specs though as the uniseal.

next used a 37/64 drill (for a 3/8-18 NPT tap) to make a feed hole for the skimmer about 1 inch down from the top of the cylindrical base. i shaved the drill bit on a bench grinder first to taper the cutting flutes to that it would tend to shave the plastic instead of tearing it, to prevent cracking. this worked very well. both drilling operaions were 2 person jobs, one to hold the skimmer body and one to drill.

i used the same bit for a drain hole in the collection cup. however, the cup was small enough to fit into a bench vise, so i cut this hole on a milling machine. because that piece seemed weaker and lacked support on the top side, i took a 6" piece of pvc and cut it down to a taper to have a nice snug fit inside the collection cup. this added a LOT of support, and made the drilling very easy with no deflection.

only problem is now I am waiting for delivery of the rio 800 as my feedpump for the skimmer, so it's basically a nice paperweight until that comes, ill update in a few days as to how much better it skims with the recirc

the last thing i did was the gate valve mod. this was necessary since i have the skimmer crammed into a 10 gal sump, and the stock setup keeps the overflow pipe crammed against the tank wall. i got the gate valve from mcmaster carr, and the rest of the fittings and pipe from home depot. it works very well to control both the output location (mine dumps right onto my chaeto to keep it clean) and the height of the water (10-turn gate valve is very precise). the output can also be moved without even using the gate valve, but i find it convenient enough to have been worth the 10 bucks the valve cost to not have to worry about the height of the exhaust.

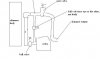

my original plan (below) to implement the recirculation mod was to not drill the skimmer at all, but instead use the sedra both as the feedpump and as the recirc pump by re-directing a portion of the outflow of the skimmer back into the sedra. i wanted to tee off the output, and stick a ball valve inline to direct some flow out the skimmer, some flow back into the sedra. the balance missing from the sedra woudl be taken from the tank. never tried this, since i had access to all i needed to mod it correctly, figured why bother with this untested setup. but if someone else was thinking of recirculating their ASM, this may be a good alternative to drilling. only one of the ball valves would have to be used, but i'm not sure which one without trying it out.

the sedra pumps 500gph. the asm recommended is to recirc w/ the 500 gph and then feed with 200gph (pump or from overflow). my big objection to using the overflow to feed the skimmer is that i didnt have a good location to tap into to feed the skimmer just due to the layout of my setup. when i move to a new place and stick my sump in the basement, i'll definitely be feeding the skimmer from the overflow.

I hope someone else can benefit in some way from my experience! also if anyone needs to use the PVC shell i made to fit the collection cup, or the 3/8-18 tap, you're more than welcome to use it.

first i thought it was acrylic, but called the company and found out it was in fact extruded PVC. it is very easy to drill.

i used a 1-3/4 hole saw to fit a 1" uniseal. i ended up not using the Uniseal brand, but another i got from McMaster Carr. Same idea, a bit more heavy duty though and a tougher rubber (which actually made it harder to get it to fit). it had the same size specs though as the uniseal.

next used a 37/64 drill (for a 3/8-18 NPT tap) to make a feed hole for the skimmer about 1 inch down from the top of the cylindrical base. i shaved the drill bit on a bench grinder first to taper the cutting flutes to that it would tend to shave the plastic instead of tearing it, to prevent cracking. this worked very well. both drilling operaions were 2 person jobs, one to hold the skimmer body and one to drill.

i used the same bit for a drain hole in the collection cup. however, the cup was small enough to fit into a bench vise, so i cut this hole on a milling machine. because that piece seemed weaker and lacked support on the top side, i took a 6" piece of pvc and cut it down to a taper to have a nice snug fit inside the collection cup. this added a LOT of support, and made the drilling very easy with no deflection.

only problem is now I am waiting for delivery of the rio 800 as my feedpump for the skimmer, so it's basically a nice paperweight until that comes, ill update in a few days as to how much better it skims with the recirc

the last thing i did was the gate valve mod. this was necessary since i have the skimmer crammed into a 10 gal sump, and the stock setup keeps the overflow pipe crammed against the tank wall. i got the gate valve from mcmaster carr, and the rest of the fittings and pipe from home depot. it works very well to control both the output location (mine dumps right onto my chaeto to keep it clean) and the height of the water (10-turn gate valve is very precise). the output can also be moved without even using the gate valve, but i find it convenient enough to have been worth the 10 bucks the valve cost to not have to worry about the height of the exhaust.

my original plan (below) to implement the recirculation mod was to not drill the skimmer at all, but instead use the sedra both as the feedpump and as the recirc pump by re-directing a portion of the outflow of the skimmer back into the sedra. i wanted to tee off the output, and stick a ball valve inline to direct some flow out the skimmer, some flow back into the sedra. the balance missing from the sedra woudl be taken from the tank. never tried this, since i had access to all i needed to mod it correctly, figured why bother with this untested setup. but if someone else was thinking of recirculating their ASM, this may be a good alternative to drilling. only one of the ball valves would have to be used, but i'm not sure which one without trying it out.

the sedra pumps 500gph. the asm recommended is to recirc w/ the 500 gph and then feed with 200gph (pump or from overflow). my big objection to using the overflow to feed the skimmer is that i didnt have a good location to tap into to feed the skimmer just due to the layout of my setup. when i move to a new place and stick my sump in the basement, i'll definitely be feeding the skimmer from the overflow.

I hope someone else can benefit in some way from my experience! also if anyone needs to use the PVC shell i made to fit the collection cup, or the 3/8-18 tap, you're more than welcome to use it.